Visited 1 times, 1 visit(s) today

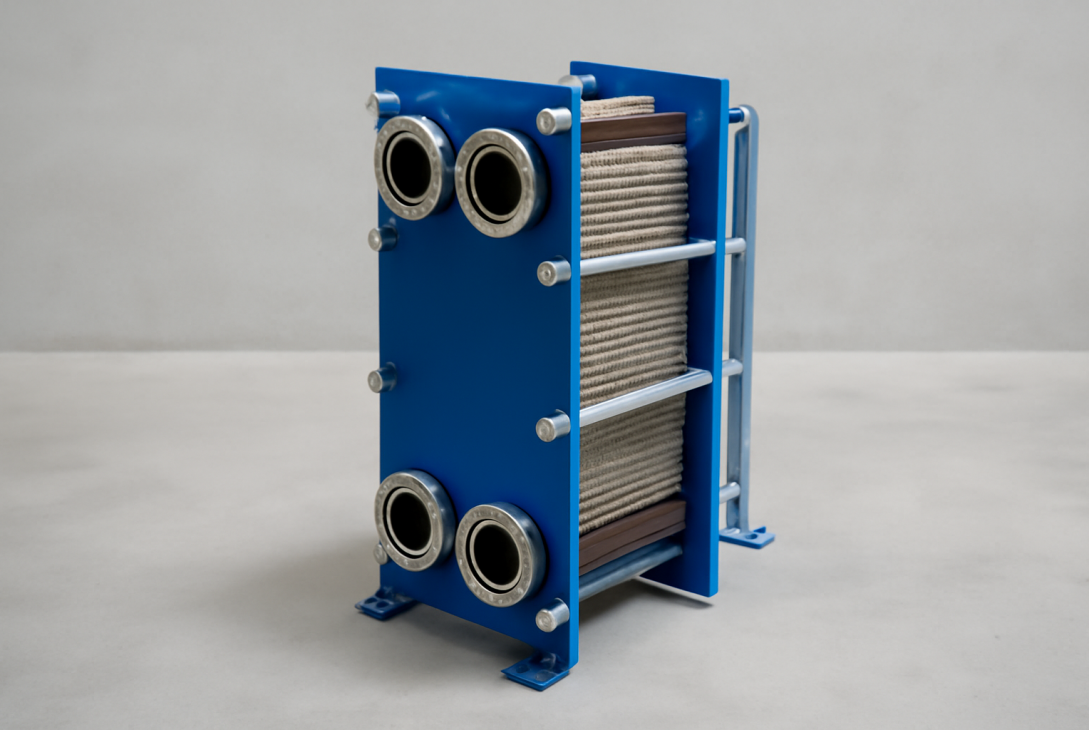

What Does a Plate Heat Exchanger Do and Why Are They Important to Industry?